3 Practical Strategies to Accelerate the Manufacturing Process

All companies strive to expedite their part manufacturing process. Faster production translates to shorter time-to-market, offering a competitive edge and bolstering profits.

While outsourcing rapid prototype design and production to third-party manufacturers might give the impression that production speed is beyond your control, this couldn’t be further from the truth. Designers and developers can play a pivotal role in accelerating on-demand manufacturing, just like the manufacturers themselves.

This article focuses on expediting the part manufacturing process, spanning from selecting the right manufacturing processes to establishing effective communication channels with manufacturers.

Choosing a fast manufacturing process

Even the best manufacturers can’t change the fact that some processes are faster than others.

That being said, you don’t always have the freedom to pick and choose between processes. If a production part needs to be cast or forged, for example, you can’t just decide to 3D print it instead. Doing so would drastically alter the function and capability of the part.

It is therefore important to determine which manufacturing processes are possible for a given project.

For rapid prototyping, there is generally a much greater degree of flexibility than with production. Most prototypes don’t have strict mechanical and material requirements, so speed can be prioritized over other factors.

Production parts have stricter requirements. However, a process that makes fast prototypes — 3D printing, for example — will not necessarily be a fast process for mass production.

CNC machining is a relatively fast manufacturing process, especially for short-run production and prototyping. It requires no tooling, and modern 5-axis machines reduce the need for multiple setups.

It is less efficient for large quantities, and there is no economy of scale: making more units doesn’t significantly reduce the time per unit. Machining complex parts also takes more time than machining simple parts.

Injection molding is a two-step manufacturing process that requires the creation of metal tooling. Because of this, it is a slow process for short-run production and prototyping.

But while making molds is a slow process, injecting shots of plastic is lightning fast. This means that each unit of the plastic part can be made very quickly once the tooling is complete. The process is therefore very fast for mass production.

It is usually obvious when a part should be made using sheet metal fabrication, so you will rarely have to decide between sheet metal and an alternative.

However, there are a range of individual processes associated with sheet metal fabrication, and the range of machinery required (brakes, shearing machines, etc.) can make rapid prototyping and short-run production slower than with all-in-one processes like CNC machining.

Designing Parts for Rapid Manufacturing

Speeding up manufacturing is not solely reliant on the manufacturer’s expertise. Product designers play a crucial role in determining the manufacturing speed of parts.

Applying Design for Manufacturability (DFM) principles will yield better parts and faster production for your on-demand manufacturing partners.

DFM for Quick Direct Feedback

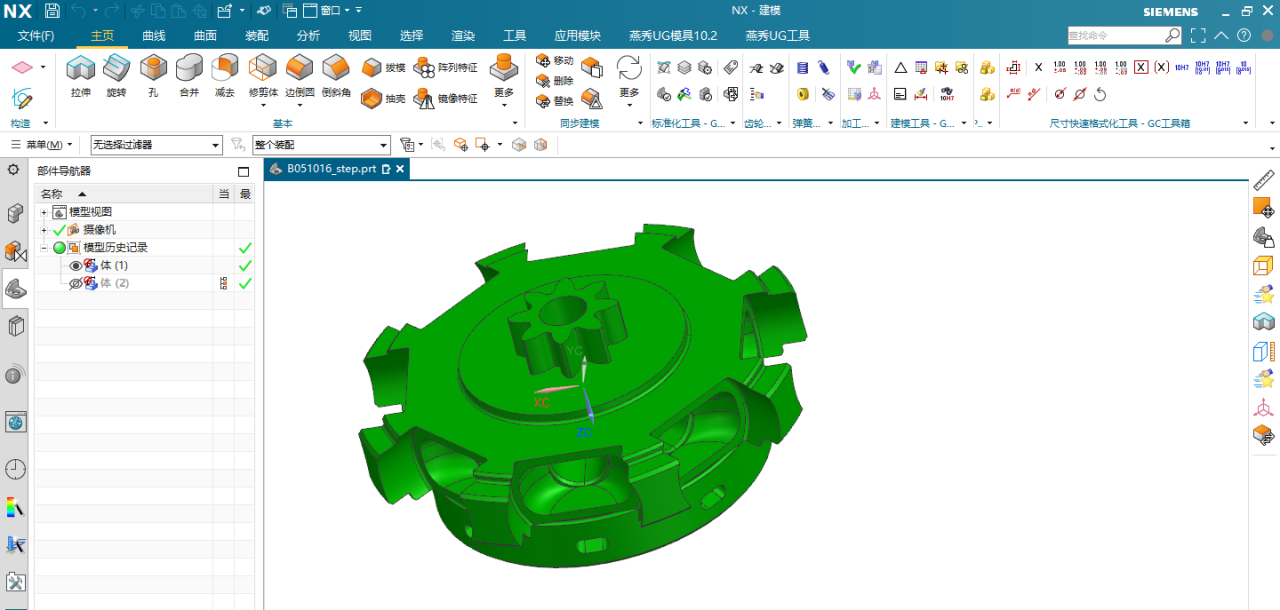

This entails considering how parts will be manufactured and tailoring designs to fit production methods, whether it’s CNC machining, injection molding, or other techniques.

However, while each manufacturing process has its unique part design standards, some general principles can be followed to expedite the manufacturing process.

Simplify Complex Features: Unnecessary complexity often makes parts harder to manufacture, increasing lead times and potentially costs. Consider if the aesthetic flourish is worth the wait.

Allow Generous Tolerances: Companies desire neat and uniform parts, but insisting on tight tolerances for non-critical dimensions can waste time. Specify strict tolerances only when absolutely necessary, allowing manufacturers to work swiftly.

Choose Machinable Materials: Material selection sometimes hinges on a part’s final use or customer preference. However, when flexibility permits, opt for materials that are easier to machine to save time. For example, CNC machines cut aluminum faster than steel.

Batch Multiple Parts per Setup: If you require multiple small-sized parts, consider CNC machining multiple units in a single setup or 3D printing multiple units on the same print bed.

Making life simple for the manufacturer

You can remove many possible ambiguities by preparing technical drawings.

Technical drawings supplement your digital design with detailed information on tolerances, surface finish requirements, annotations and other requirements not shown in the CAD file itself.

Technical drawings can also be supplemented by notes to the manufacturer in which you can explain your objectives and requirements in natural language. Making these notes clear and unambiguous means that you don’t need to continue discussing the project with the manufacturer.

Of course, communicating your needs to the manufacturer becomes easier when you’re working with the same people time and time again. Instead of looking for new partners on a project-by-project basis, consider building a long-term relationship with the manufacturer; you’ll find fewer miscommunications and faster production over time.