XY-Global: Precision CNC Machining & Die Casting Manufacturer

XY-Global stands as a premier international manufacturer, distinguished for its mastery in high precision CNC machining and the fabrication of top-tier aluminum and zinc die casting products. Our unwavering commitment to excellence is ingrained in our tailored CNC machining solutions and impeccable die-cast parts crafted from premium aluminum and zinc alloys.

Precision manufacturing, we uphold the utmost quality standards while ensuring competitive pricing and unparalleled service excellence. Our extensive array of services encompasses bespoke die-cast parts and customized aluminum components, solidifying our stature as an unrivaled industry leader.

Lifetime Warranty

Professional Engineering Team: Our engineering team members each have over 10 years of experience in the field. With their rich experience and solid technical skills, they are capable of delivering high-quality services to meet your needs.

High-Precision Measuring Equipment: We adhere to strict product quality testing standards and utilize advanced high-precision measuring equipment. This ensures that our products are of high quality and consistency, contributing to the enhancement of your product development and market competitiveness.

Local Support

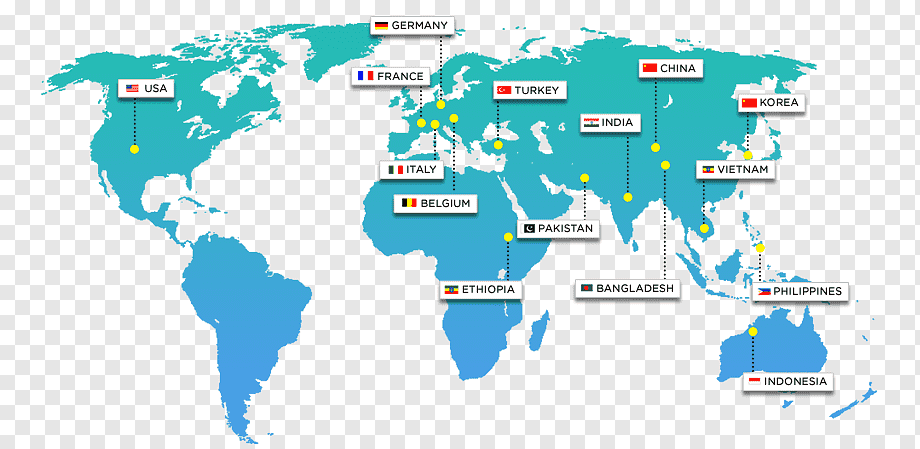

XY-Global boasts dedicated manufacturing and assembly facilities strategically located in Johor, Malaysia, and Shenzhen, China, augmented by precision machining capabilities. Additionally, we maintain sales offices across Europe, ensuring seamless access to our exceptional services for customers worldwide.

Our Family

ISO Certificate

Production Capacity

XY-Global has advanced production facilities and a well-established manufacturing process. We have a modern manufacturing and assembly plant covering an area of 5000 square meters, equipped with 5 high-precision lathes, 3 CNC machine tools, and 1 five-axis CNC machining center.

Our production capacity covers multiple fields including high-precision CNC machining, aluminum and zinc die casting, surface treatment, and more. Whether it’s small-batch custom production or large-scale mass production, we can meet the needs of our customers.

Tooling Production Schedule

If you provide existing part drawings, eliminating the need for additional design, the manufacturing lead time will be reduced accordingly. Additionally, we will provide a manufacturing schedule for each process stage and update it weekly to our clients to ensure on-time delivery.

Professional DFM & Moldflow Analysis Report Support

Before the tooling, we will offer a detailed DFMand mold flow report to confirm the designfrom our customers are feasible for production.

Prototype & Solution Support

We know how the sample trial is needed in theEVT and DVT stages. That is why we strive toprovide our ideas and do the processes ofverification to support our customers' prototypetesting. Solution service production is the coreof our team. We are willing to provide oursolution in structure, dimension tolerance, andsurface treatment to help our customersupgrade and fulfill their designs.