Injection Molding Services

Looking for a reliable rapid prototyping and production partner? We can help. Get an online quote with free analysis in hours for quality parts within days.

- Online instant pricing & Free DFM

- Rapid prototype as far as 2 days

- Tight tolerance controllinto +/- 0.01mm

- Overview

- Feature

- Materials

- Finishes

- Why Choose Us

- Resources

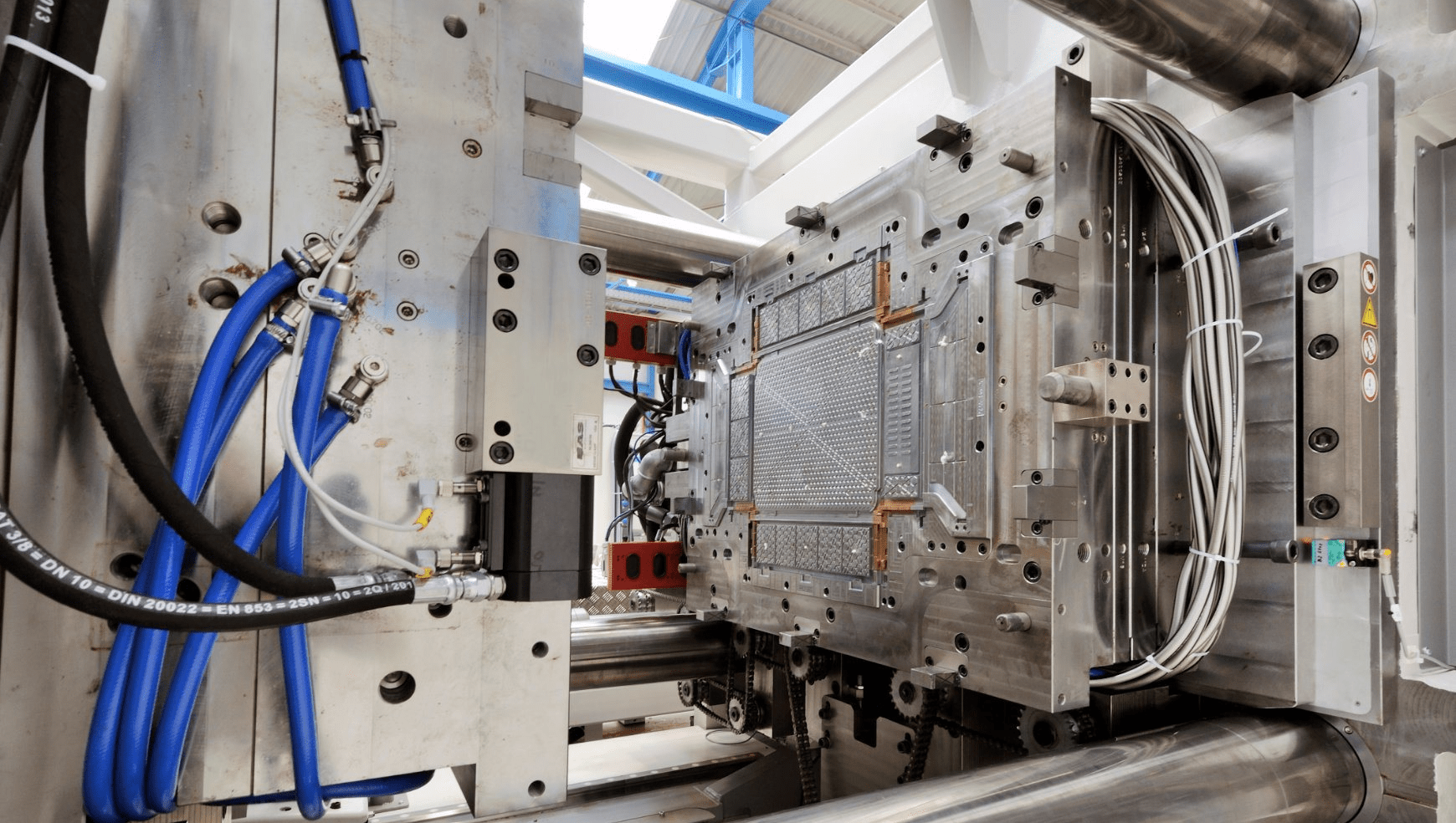

Injection Molding Small Batch Molding

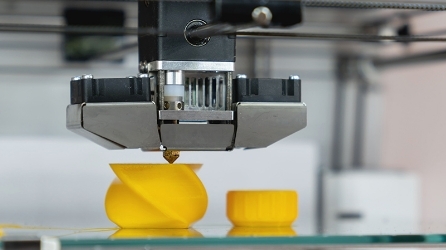

From Prototyping to Production

With years of manufacturing experience, XY-GLOBAL provides the best solutions for all rapid prototyping, low-volume manufacturing, and high precision injection moulding needs. We simplify the innovation cycle into four simple but effective steps, ensuring that your projects are executed with utmost precision and efficiency.

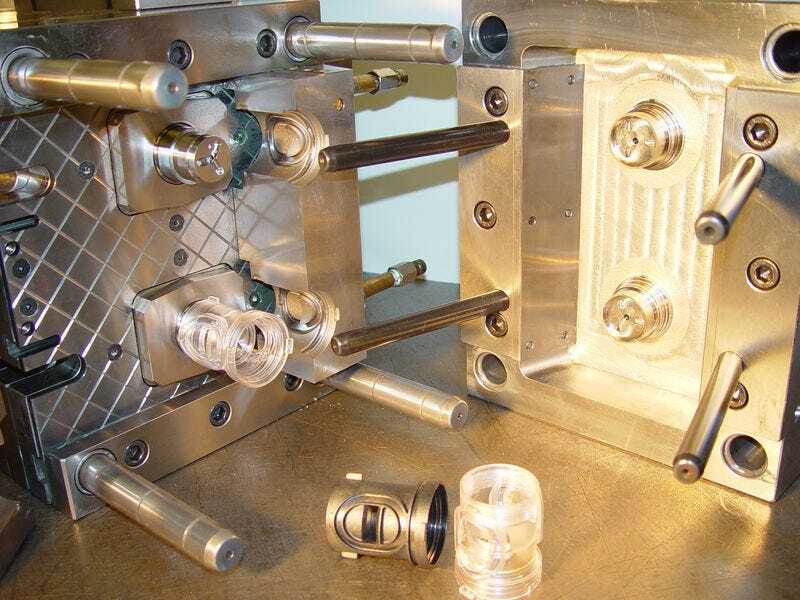

Small Molded Parts within Days

Our complete injection molding services will accompany your processing project from prototype construction to final part manufacturing.

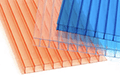

Common Materials for Injection Molding

There are many types of materials that can be used for injection molding. XY-GLOBAL provides processing quotations for more than 30 types of engineering grade plastics.

We can source any other materials upon request! If you don’t see the material you need please contact us

Injection Molding Surface Treatment Options

You may pick from a variety of secondary operations that create final production parts, such as heat treating, tapping, reaming, and post-process machining.

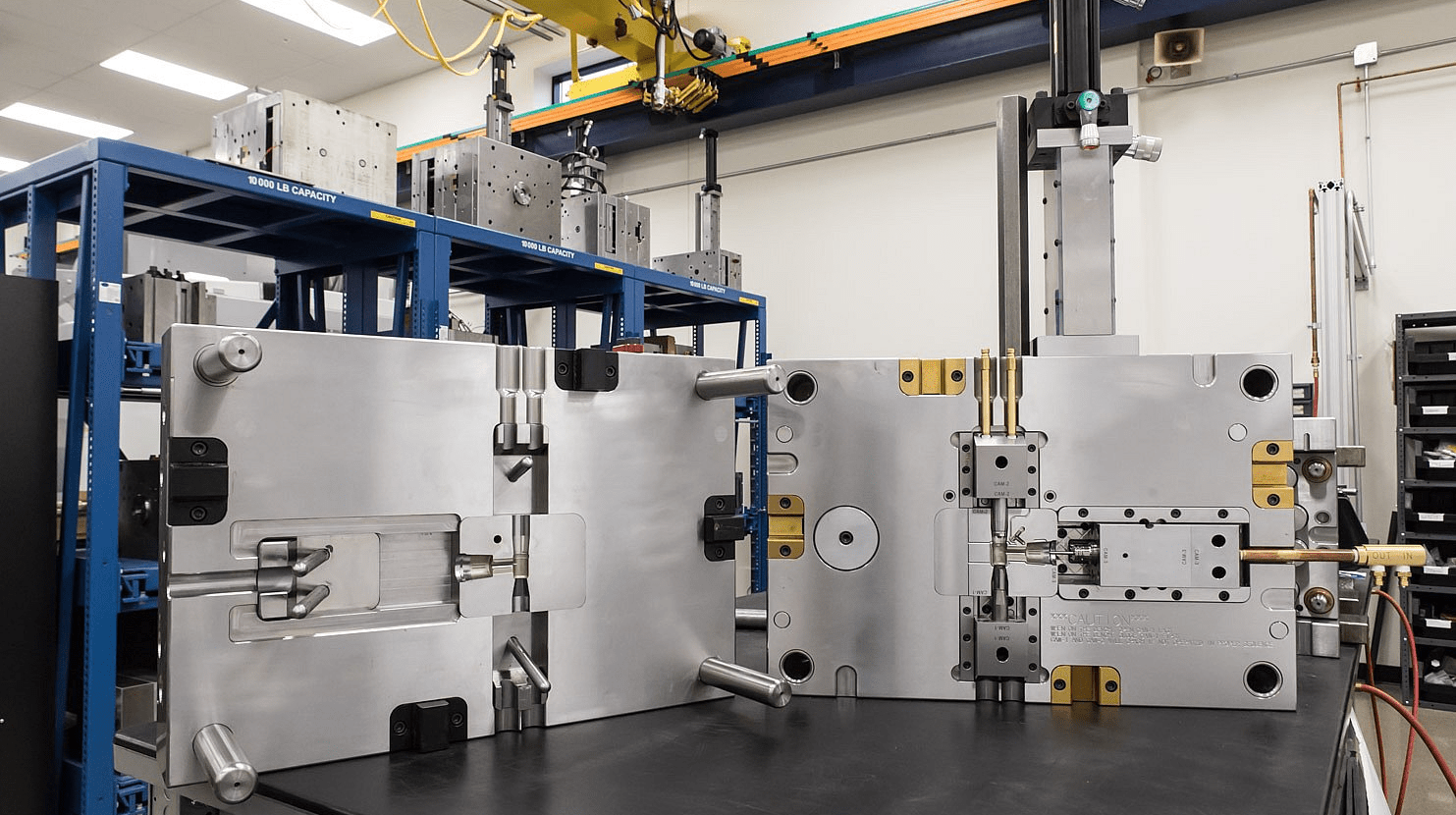

Why Choose Us?

XY-GLOBAL is a one-stop solution platform, from prototype design, R&D to mass production, our strong production capacity, comprehensive services and strong quality control can quickly help you enhance your brand.

- Can make up for the risk of large capital investment before mass production.

- Diversified production materials and styles.

- Customers can grasp the production details at any time, and understand the production progress at any time.

- Some other features can be added to the parts in production, which are not restricted by the mold.

Industry Application

We’ve manufactured millions of parts for all sorts of applications, empowering diverse industries with top-notch products: industrial machinery, medical, AI industrial,Transportation, etc.

Injection Molding FAQs

What are the main advantages of injection molding?

What are the main materials used in the injection molding process?

What common problems may be encountered during injection molding?

What is the minimum order quantity for injection molding?

Manufacturing Resources

Put your parts into production today