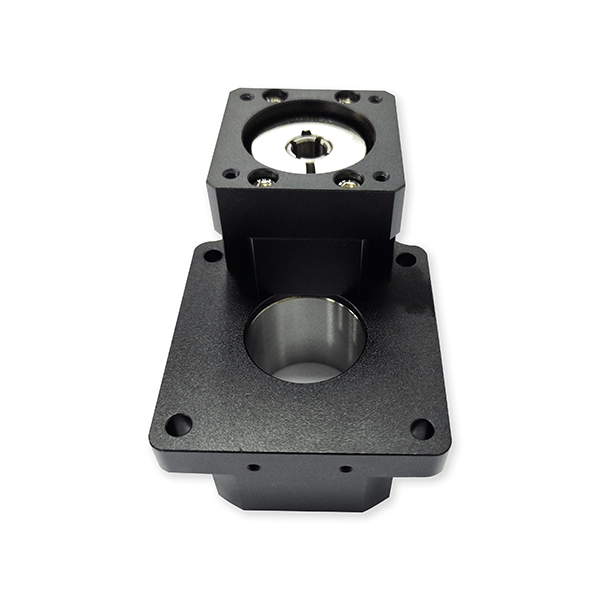

Motorised hollow rotary platforms

OTHER configuration:

Material: aluminium alloy + steel

Bearings: Crossed tapered roller bearings

Process: Milling – Anodizing – Deburring

Annual volume: 500-1000PCS

Features: Tolerance 0.006mm

Processing difficulties: Through-hole burrs are not easy to remove

Process Chamber

OTHER configuration:

| Chamber Materials | The materials used to construct the chamber, i.e., stainless steel, may be preferable due to its high resistance to corrosion. |

| Size | A larger chamber may be needed for accommodating larger substrates or creating multi-chamber systems. |

| Pumping Speed | The pumping speed should match the expected outgassing rates of the system. Turbo pumps or oil-free pumps may be preferred depending on requirements. |

| Ultimate Pressure Requirements | This will depend on the required level of precision for the particular process being conducted; keeping low levels of residual gas is imperative where necessary. |

| Process Gas Compatibility | Some materials react with certain gases in ways that may not support effective processing and achieving desirable results. Compatibility must therefore be determined. |

Semiconductor equipment bases

OTHER configuration:

Material: SUS316

Process: Wire cutting, Milling ,Double side grinding, Lettering

Annual volume: 6000 PCS

Features: 0.5 small cutter processing, intersection hole burr not easy to remove

Semiconductor equipment connectors

OTHER configuration:

Material: SUS304/316

Process: turning-milling-polishing deburring

Annual volume: 400,000-600,000 PCS

Features: the material is not easy to cut, cross-hole burr is not easy to remove, high appearance requirements

Semiconductor equipment connectors

OTHER configuration:

Material: SUS304/316

Process: turning-milling-polishing deburring

Annual volume: 400,000-600,000 PCS

Features: the material is not easy to cut, cross-hole burr is not easy to remove, high appearance requirements

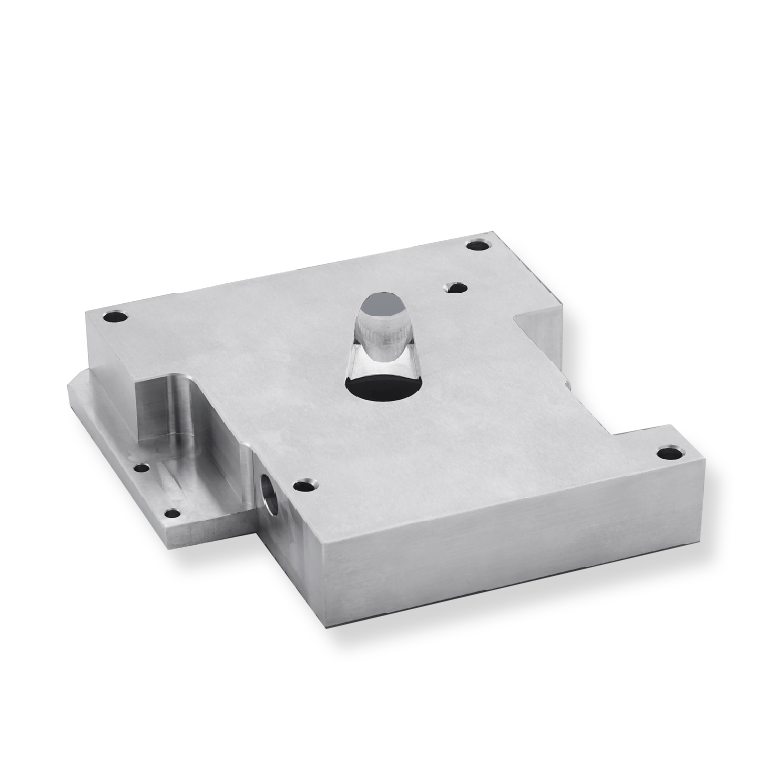

Semiconductor equipment parts

OTHER configuration:

Material: SUS304

Process: Milling -Surface grinding

Annual volume: 1000-2000PCS

Processing difficulties: flatness 0.01, cross hole burr removal

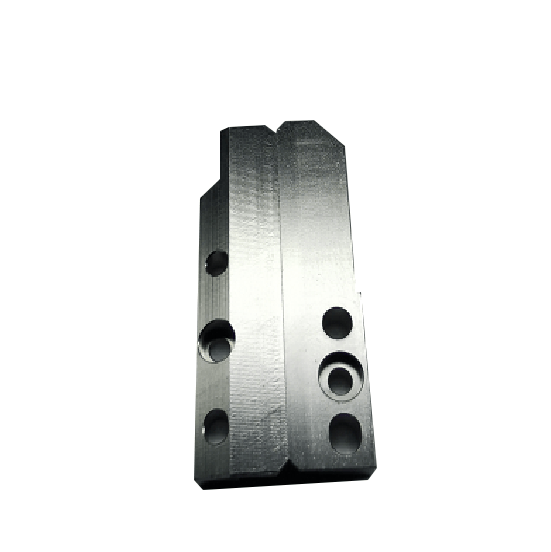

Semiconductor equipment platens

OTHER configuration:

Material: SUS304

Process: milling – grinding and polishing

Annual volume: 2000-3000PCS

Processing difficulties: thin structure of the workpiece is easy to deformation, parallelism 0.01

Semiconductor equipment support frame

OTHER configuration:

Material: SUS304/316

Process: turning-milling-polishing deburring

Annual volume: 400,000-600,000 PCS

Features: the material is not easy to cut, cross-hole burr is not easy to remove, high appearance requirements

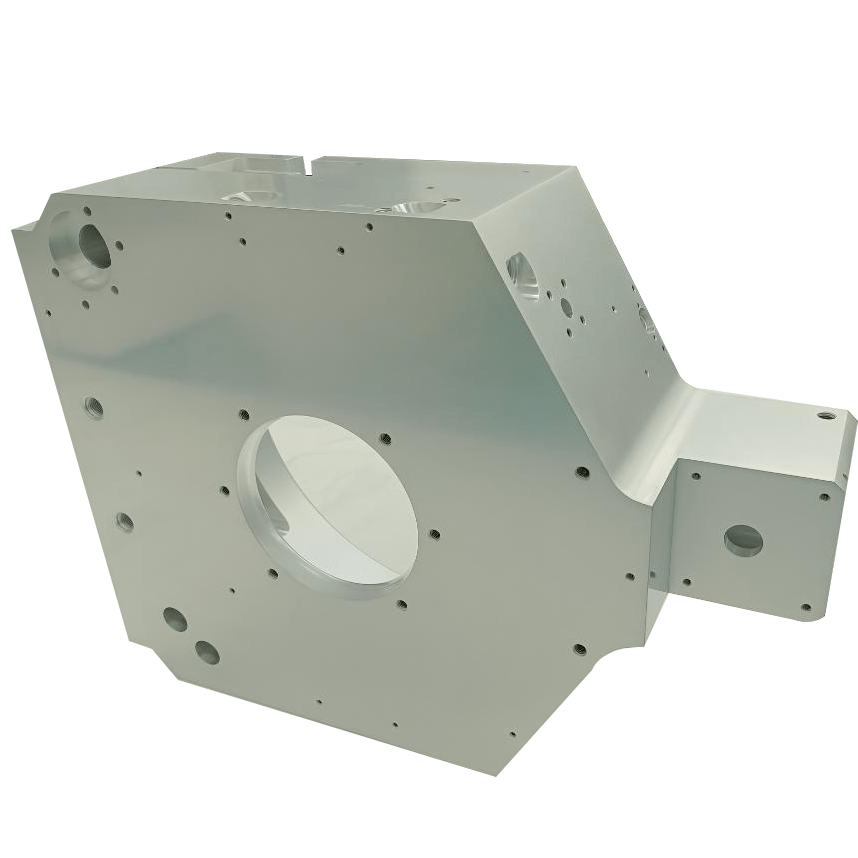

Semiconductor valve block

OTHER configuration:

Material: 6061-T6

Process: Milling – Anodizing – Deburring – Laser engraving

Annual volume: 500-1000PCS

Features: Tolerance 0.006mm

Processing difficulties: Through-hole burrs are not easy to remove

vacuum chamber

OTHER configuration:

| Chamber Materials | The materials used to construct the chamber, i.e., stainless steel, may be preferable due to its high resistance to corrosion. |

| Size | A larger chamber may be needed for accommodating larger substrates or creating multi-chamber systems. |

| Pumping Speed | The pumping speed should match the expected outgassing rates of the system. Turbo pumps or oil-free pumps may be preferred depending on requirements. |

| Ultimate Pressure Requirements | This will depend on the required level of precision for the particular process being conducted; keeping low levels of residual gas is imperative where necessary. |

| Process Gas Compatibility | Some materials react with certain gases in ways that may not support effective processing and achieving desirable results. Compatibility must therefore be determined. |