BT-ER tool holder

OTHER configuration:

Features:

Made of Japanese Daido SCM415 carburised steel with a core tensile strength of ≥950N/mm

Tool shank hardness of HRC54-56

Taper tolerance in accordance with AT3 grade, with a standard machine spindle fit surface of more than 90%

True roundness of internal and external taper ≤ 0.001mm, roughness ≤ Ra0.4

With cartridge and tool installed, tool runout is tested at ≤0.005mm when extended 5 times

Dynamic balance 100% inspection, meet 30000RPM, dynamic balance for G2.5

BT-Powerful Tool Holder

OTHER configuration:

Features:

Made of Japanese Daido SCM415 carburised steel with a core tensile strength of ≥950N/mm

Tool shank hardness of HRC54-56

Taper tolerance in accordance with AT3 grade, with a standard machine spindle fit surface of more than 90%

True roundness of internal and external taper ≤ 0.001mm, roughness ≤ Ra0.4

With cartridge and tool installed, tool runout is tested at ≤0.005mm when extended 5 times

Dynamic balance 100% inspection, meet 30000RPM, dynamic balance for G2.5

BT30 ER11 Collet Chuck Tool Holder For Cnc milling lathe machine

OTHER configuration:

Features:

Made of Japanese Daido SCM415 carburised steel with a core tensile strength of ≥950N/mm

Tool shank hardness of HRC54-56

Taper tolerance in accordance with AT3 grade, with a standard machine spindle fit surface of more than 90%

True roundness of internal and external taper ≤ 0.001mm, roughness ≤ Ra0.4

With cartridge and tool installed, tool runout is tested at ≤0.005mm when extended 5 times

Dynamic balance 100% inspection, meet 30000RPM, dynamic balance for G2.5

| Quantity (pieces) | 1 – 30 | 31 – 500 | 501 – 1000 | > 1000 |

| Lead time (days) | 7 | 15 | 25 |

To be negotiated |

Customization:

Customized logo (Min. order 100 pieces)

Graphic customization (Min. order 100 pieces)

Customized packaging (Min. order 100 pieces)

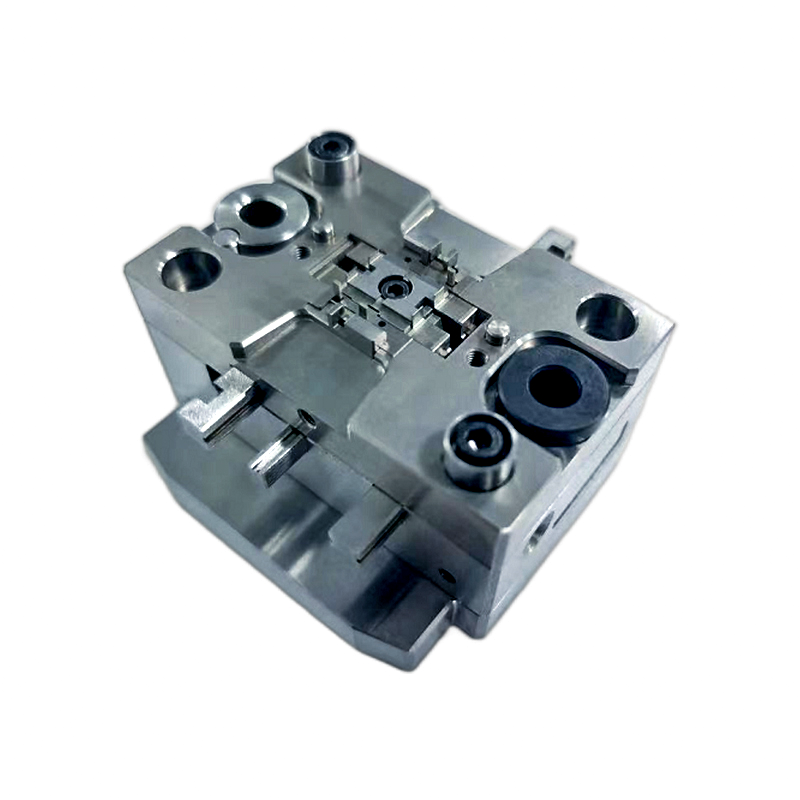

Customized High Precision Machining Fixture, Jigs

OTHER configuration:

Features:

1. Non-slip, stable and durable.

2. Protect the workpiece and increase the friction force

3. Fast loading and unloading of workpieces, saving time and effort

4. Improve processing and safety efficiency

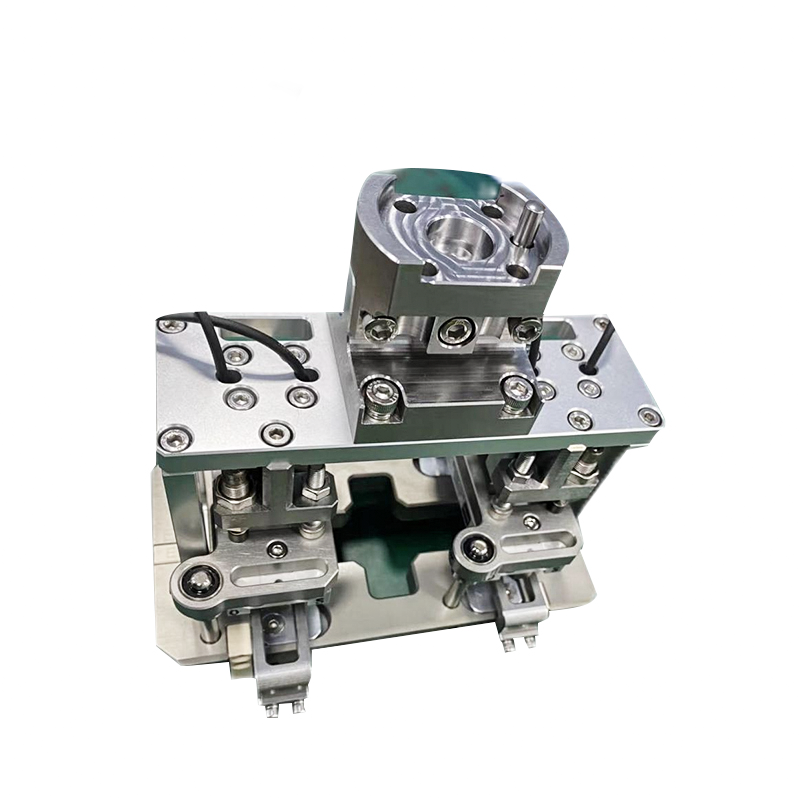

High Precision Aluminum Fixture, Jigs

OTHER configuration:

Features:

1. Non-slip, stable and durable.

2. Protect the workpiece and increase the friction force

3. Fast loading and unloading of workpieces, saving time and effort

4. Improve processing and safety efficiency

High Precision CNC spindle tool holder ISO10

OTHER configuration:

Features:

Made of Japanese Daido SCM415 carburised steel with a core tensile strength of ≥950N/mm

Tool shank hardness of HRC54-56

Taper tolerance in accordance with AT3 grade, with a standard machine spindle fit surface of more than 90%

True roundness of internal and external taper ≤ 0.001mm, roughness ≤ Ra0.4

With cartridge and tool installed, tool runout is tested at ≤0.005mm when extended 5 times

Dynamic balance 100% inspection, meet 30000RPM, dynamic balance for G2.5

High Precision Stainless Steel Fixture, Jigs

OTHER configuration:

Features:

1. Non-slip, stable and durable.

2. Protect the workpiece and increase the friction force

3. Fast loading and unloading of workpieces, saving time and effort

4. Improve processing and safety efficiency

High Precision Stainless Steel Fixture, Jigs

OTHER configuration:

Features:

1. Non-slip, stable and durable.

2. Protect the workpiece and increase the friction force

3. Fast loading and unloading of workpieces, saving time and effort

4. Improve processing and safety efficiency

High Precision Stainless Steel Fixture/Jigs

OTHER configuration:

Features:

1. Non-slip, stable and durable.

2. Protect the workpiece and increase the friction force

3. Fast loading and unloading of workpieces, saving time and effort

4. Improve processing and safety efficiency

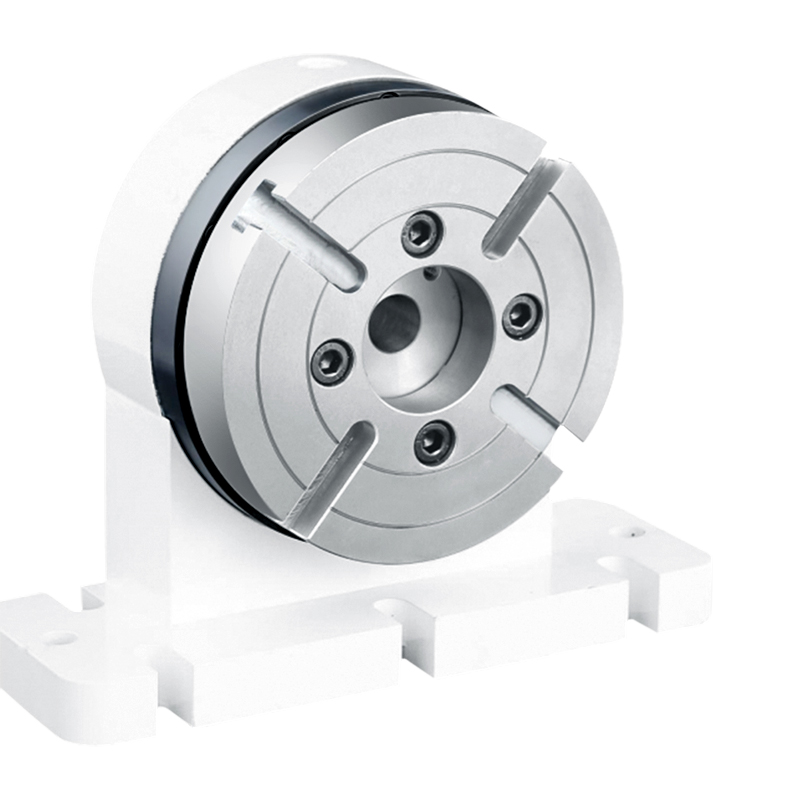

PRECISE 6 & 8 JAW

OTHER configuration:

Features:

1. Non-slip, stable and durable.

2. Protect the workpiece and increase the friction force

3. Fast loading and unloading of workpieces, saving time and effort

4. Improve processing and safety efficiency

Product use:

1. Used on CNC lathes for processing thin-walled or machined parts with very precise requirements for roundness and concentricity

2. Effective in preventing product deformation or poor quality stability during machining

PRECISE 6 & 8 JAW

OTHER configuration:

Features:

1. Non-slip, stable and durable.

2. Protect the workpiece and increase the friction force

3. Fast loading and unloading of workpieces, saving time and effort

4. Improve processing and safety efficiency

Product use:

1. Used on CNC lathes for processing thin-walled or machined parts with very precise requirements for roundness and concentricity

2. Effective in preventing product deformation or poor quality stability during machining

PRECISE COLLET

OTHER configuration:

Features:

Made of high quality Japanese SUJ2 bearing steel

Adopt heat treatment + deep cooling process, hardness HRC50

Adopt inside and outside diameter grinding and then break open the processing technology

Extend 5 times the length of the diameter, compound accuracy ≤ 0.005mm

Can clamp the corresponding specifications of drill, milling cutter, reamer, tapping

Pull Stud Nut Series

OTHER configuration:

1. Adopting high quality 20CrMoTi carburised structural steel.

2. Adopting roughing+carburising+finishing technology

3. Pre-set dynamic balancing, higher precision

4. Sturdy and wear-resistant, stronger clamping force, no loosening and deformation.

ROTARY TAILSTOCK SERIES

OTHER configuration:

Features:

1. Non-slip, stable and durable.

2. Protect the workpiece and increase the friction force

3. Fast loading and unloading of workpieces, saving time and effort

4. Improve processing and safety efficiency

· The main body is made of high quality alloy structural steel 42CrMo + open rough + tempered heat treatment process

· Spindle made of high quality steel from Great Wall Special Steel + heat treatment + grinding process

· Japan NSK double cone bearing, oil seal and other accessories are adopted

· Runout meets within 0.005mm

· Adopt air brake design, more sensitive, more stable

SWISS-TYPE LATHE SERIES

OTHER configuration:

Features:

1. Non-slip, stable and durable.

2. Protect the workpiece and increase the friction force

3. Fast loading and unloading of workpieces, saving time and effort

4. Improve processing and safety efficiency