Advantages of different guide rails in cnc machining

CNC machining generally refers to computer digital control precision machining, which is mainly used for the machining of precision hardware parts. Let’s take a look at the advantages of different guide rails in CNC machining.

1. There is an oil cavity between the two guide rail working surfaces of the hydrostatic guide rail. After the lubricating oil with a certain pressure is introduced, a hydrostatic oil film can be formed, so that the working surface of the guide rail is in pure liquid conflict, no wear, and precision. Good persistence; at the same time, lubricating oil without a certain pressure can form a static pressure oil film to keep the working surface of the guide rail clean and has good impact resistance. Hydrostatic guide rails can be divided into hydrostatic guide rails and gas static pressure guide rails.

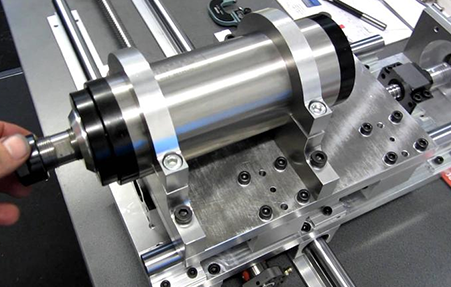

2. The slide rail has the advantages of simple structure, convenient manufacture, high rigidity and high anti-vibration. PTFE guide rail soft tape and epoxy wear-resistant guide rail coating are commonly used guide rail plastics. The plastic-coated slider is characterized by good impact performance, good wear resistance, smooth movement, vibration damping performance and manufacturability.

Which one is better for CNC processing

3. Rolling guide rail is to place rolling bodies such as balls, rollers, needle rollers, etc. between the guide rail surfaces, so that the sliding conflict between the guide rail surfaces becomes a rolling conflict. Compared with sliding guide rails, the advantages of tumbling guide rails are: high flexibility, and the difference between the dynamic conflict coefficient and the static conflict coefficient is very small, so it is not easy to appear creeping phenomenon when moving at low speed; (high positioning accuracy, high repeat positioning accuracy, Small wear, low precision requirements, easy to wear), low precision requirements, long life. However, the anti-vibration performance of rolling guides is poor, and the protection requirements are relatively high.