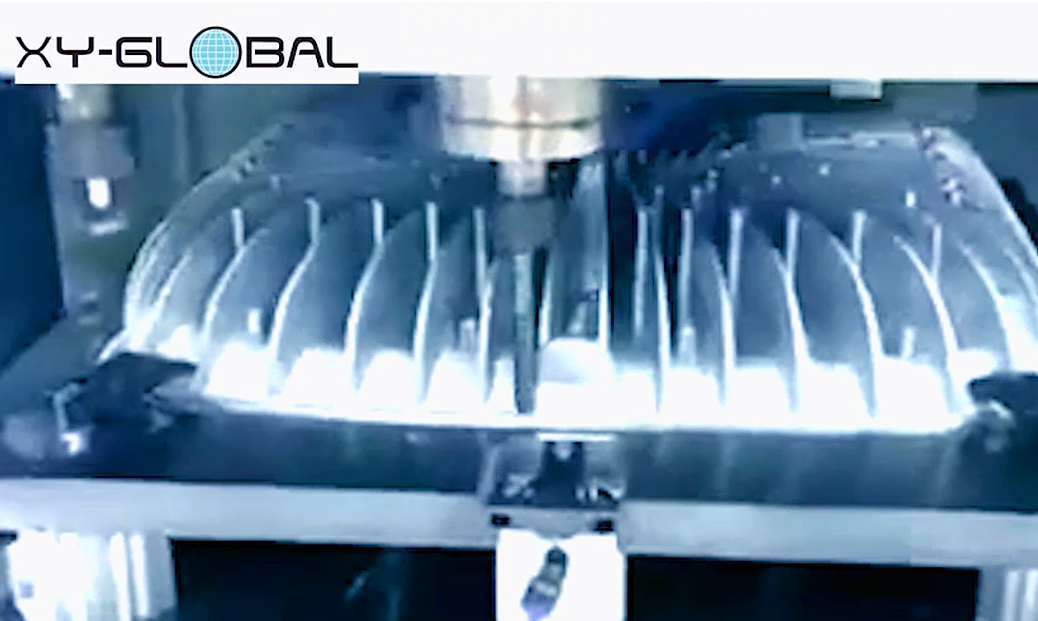

CNC aluminum alloy custom processing

How to improve the efficiency of CNC aluminum alloy custom processing, there are a few points as follows:

1. Selection of tools

When choosing a tool, it is necessary to correctly select the tool according to the processing capacity of the machine tool, material properties, processing procedures, cutting amount, etc. A suitable tool can not only ensure product quality but also improve processing efficiency.

2. Determination of cutting amount

The principle of reasonable selection of cutting amount is to improve the production efficiency during rough machining, and the premise of finishing machining should ensure the machining quality, and then try to improve the machining efficiency.

3. Determination of tool running path

The tool trajectory depends on the programming skills of the programmer. The programmed trajectory determines the processing cycle of the aluminum alloy shell. Shortening the non-processing time and reducing unreasonable tool changes are beneficial methods to improve the processing efficiency.