Customized Parts – 3D Printing Services

3D Printing Processes

Our online 3D printing service enables you to 3D print your custom part on demand. We offer six 3D printing technologies to transform your 3D files into plastic, metal, and elastomeric parts. With more than 120 3D printers, we have unmatched capacity that reliably delivers parts within days. In addition to a broad material selection, we offer several post-processing options to improve cosmetics or enhance mechanical properties.

Metal 3D Printing

Direct metal laser sintering (DMLS) uses a fiber laser system that draws onto a surface of atomized metal powder, welding the powder into fully dense metal parts.

Multi Jet Fusion (MJF)

Multi Jet Fusion selectively applies fusing and detailing agents across a bed of nylon powder, which are fused in thousands of layers by heating elements into a solid functional component.

Stereolithography (SLA)

Stereolithography (SLA) uses an ultraviolet laser that draws on the surface of liquid thermoset resin to create thousands of thin layers until final parts are formed.

PolyJet

PolyJet uses a jetting process where small droplets of liquid photopolymer are sprayed from multiple jets onto a build platform and cured in layers that form elastomeric parts.

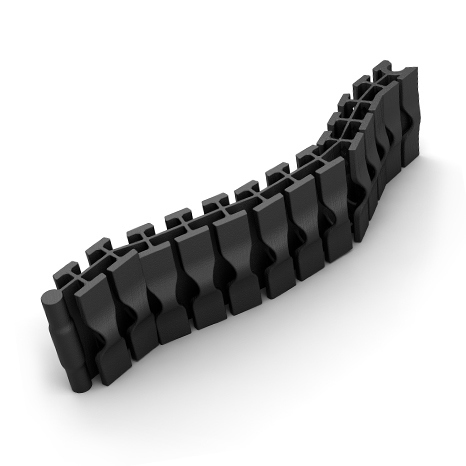

Selective Laser Sintering (SLS)

Selective laser sintering (SLS) uses a CO2 laser that fuses nylon-based powder, layer by layer until final thermoplastic parts are built.

Carbon DLS

Carbon DLS uses digital light projection, oxygen permeable optics, and programmable liquid resins to produce plastic parts with excellent mechanical properties and surface finish.

How can 3D printing technology help healthcare?

Customized Medical Devices and Equipment: 3D printing can be used to create customized medical devices and equipment such as prosthetics, orthotics, dental braces, etc. These devices can be customized to a patient’s specific anatomy and needs, improving treatment outcomes and patient comfort.

Bioprinting:3D printing technology is also used for bioprinting, which is the printing of human tissues and organs. This technology is expected to be used in experimental studies prior to organ transplantation to provide better treatment options for patients. Currently, a number of small tissues have been successfully printed in a laboratory setting, although the challenge of bioprinting entire organs remains.

Surgical Models: 3D printing can create accurate anatomical models that help doctors simulate actual operations before surgery. This helps to improve the accuracy and reduce the risk of surgery.

Drug customization:3D printing technology can be used to create personalized medications, tailoring the dosage and shape of the drug to the specific needs and physiological characteristics of the patient, improving the effectiveness of the treatment.

Medical Devices and Components: 3D printing can be used to produce medical devices and components, such as patient-specific surgical tools, surgical aids, support and immobilization devices, and more. This customized production can be better adapted to the patient’s needs.

DENTAL APPLICATIONS: 3D printing has a wide range of applications in the field of dentistry, including the production of crowns, bridges, dentures, and more. This not only improves productivity but also provides better personalized solutions.

Medical Education:3D printing technology provides high-quality anatomical models for use in medical education, helping medical students better understand human structures and organs.

General Tolerances for 3D Printing

For linear dimensions that are printed without specified tolerances, our local 3D printing shops adhere to the GB 1804-2000 standard, applying and inspecting with a coarse accuracy level (Class C).

For shape and position dimensions not noted tolerance, we follow the GB 1804-2000 L level for implementation and testing. Refer to the following table:

|

| Basic Size |

| Linear Dimensions | ±0.2 to ±4 mm |

| Fillet Radius and Chamfer Height Dimensions | ± 0.4 to ± 4 mm |

| Angular Dimensions | ±1°30′ to ±10′ |

|

| Basic Length |

| Straightness and Flatness | 0.1 to 1.6 mm |

| Verticality Tolerance | 0.5 to 2 mm |

| The Degree of Symmetry | 0.6 to 2 mm |

| Circular Runout Tolerance | 0.5 mm |

Why choose us for custom 3D printing?

1. Unrivalled Quality

Get design feedback from our experienced engineering team that has helped thousands of customers bring their products to market with quality 3D printed parts. We will also work with you to determine the best part orientation for your application requirements.

2. Ask for a Quote

Our industry-leading tolerances and surface finish quality result from dedicated process engineering and quality teams for each 3D printing technology.

3. Wide range of material options

Across our six 3D printing technologies, we use a range of commercial-grade thermoset resins, thermoplastics, and metal powders to 3D print parts suitable for a variety of part applications and industries. If your part requires it, we can offer a variety of post-processing options such as heat treating, secondary operations, plating, painting, and colouring to further enhance mechanical properties and appearance.

4. Size and Production

Our facility has over 120 3D printers producing metal and plastic parts. This means that when you need parts quickly, whether it’s a small batch of parts or a production level batch, we always have the capacity.

Common 3D Printing Applications

Additive manufacturing can be leveraged for both rapid prototyping and production in aerospace, medical, automotive, and other large industry sectors. Examples of typical parts, include:

- · Form and fit prototypes

- · Housings and enclosures

- · Medical devices

- · Snap fits

- · Jigs and fixtures

- · Heat exchangers and heat sinks

- · Engine components

- · Fuel injectors

- · Surgical instrumentation

Get a Quote for Your 3D Print

Upload a 3D CAD file to us at :sales820@xy-global.com.

Our team of engineers will be the first to contact you and analyse your project. If you have any questions about the quote or design, you can also work with our application engineering team who will help guide you through the process.