Machine parts repair methods and techniques

Wear, scratches and dimensional tolerances of machine parts account for about 70% of machine part failures.

Due to the high strength and hardness of the parts, the production and operation process is subject to vibration, impact and other compound forces, often resulting in a “hard-to-hard” relationship between metal parts, resulting in partial impact deformation into permanent deformation, recovery stress reduction, the formation of gaps, resulting in relatively low hardness of the parts wear. Therefore, for the repair of machine parts, the use of polymer repair or brushing and cold welding techniques is a very effective method.

Traditional repair methods include processes such as surface welding, thermal spraying, and electric brushing. However, these methods can cause the surface of the parts to reach high temperatures for temperature-sensitive metal parts, which can deform or crack the parts and affect the dimensional accuracy and normal use of the parts, and even cause serious consequences such as shaft fracture.

Traditional repair methods include processes such as surface welding, thermal spraying, and electric brushing. However, these methods can cause the surface of the parts to reach high temperatures for temperature-sensitive metal parts, which can deform or crack the parts and affect the dimensional accuracy and normal use of the parts, and even cause serious consequences such as shaft fracture.

In contrast, the use of polymer materials for repair, can be integrated product performance and machining advantages, not only to meet the use and accuracy requirements after repair, but also to reduce the impact and vibration of equipment in the process of operation and long operation, extending the service life. As the material is “variable” than when the external force impacts the material, the material deforms and absorbs the external force, and expands and contracts with the thermal expansion and contraction of the bearing or other components, and always maintains a tight fit with the material to reduce the possibility of wear. We call this the “shrinkage effect”.

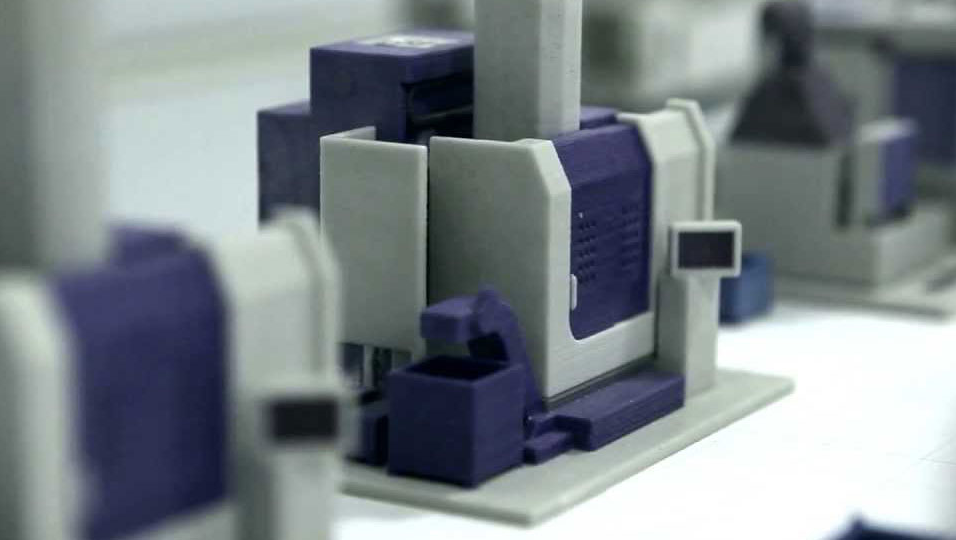

In the case of large equipment wear, it is also possible to use a “mold” or “kit” to repair the damaged equipment on site, avoiding a large body vibration removal of the equipment. This method can ensure the maximum dimensional accuracy of the parts, meet the production and operation requirements of the equipment, extend the service life of the equipment, ensure the life cycle of the company, and guarantee the safety and continuous production of the company.

In addition, brush coating and cold welding technology is also an efficient repair method. This technology can improve the wear resistance, corrosion resistance, high temperature resistance and surface hardness of the parts, and the bond between each machine part after repair is strong and not easy to fall off. Moreover, the technology is fast and can be repaired quickly.

In addition, for the case of large equipment wear, we can also use the mold or supporting parts to repair the damaged equipment on site, to avoid the large body of equipment vibration unloading. This method can maximize the four matching dimensions of the parts to meet the production operation requirements of the equipment, while extending the service life of the equipment and ensuring the production safety and continuity of the company.

When repairing machine parts, we also use brush coating and cold welding techniques. These repair methods can improve the wear resistance, corrosion resistance, high temperature resistance and surface hardness of the parts, while the repaired parts will not warp, anneal, gnaw on the edges, or damage the base material or soften. In addition, these repair methods are fast and inexpensive to repair, and the dimensional accuracy of each part can be guaranteed without re-rotation after repair.

The plating material we use has a hardness of HRC25-60, which is characterized by high hardness, wear resistance, high temperature resistance and corrosion resistance. During the coating process, the surface temperature of the parts is always kept below 70 degrees, which avoids the influence of temperature on the parts.

In general, wear, scratches and dimensional tolerances of machine parts account for about 70% of machine part failures. Therefore, it is very important to maintain and repair machine parts in time during production and operation. As a professional manufacturer of machine parts, we have rich manufacturing experience in this field and have standardized production facilities and strict quality inspection system to control product quality in all aspects. Meanwhile, we also provide effective solution technology and considerate one-stop service to meet customers’ needs. If you are interested in our machine parts, please feel free to contact us.