Precautions for daily operation of large CNC machining

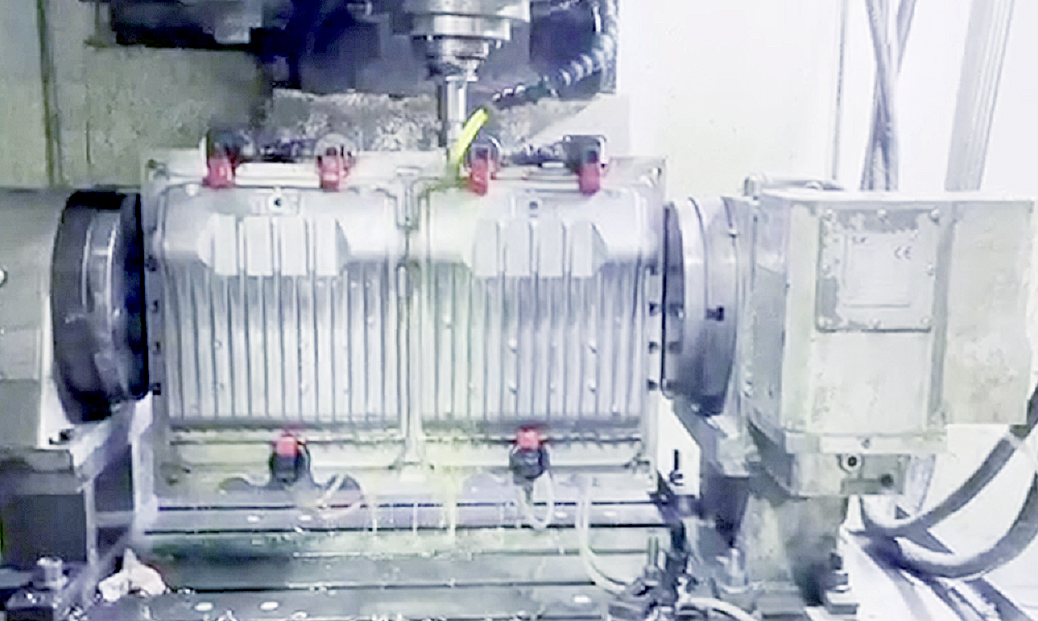

CNC machining generally refers to the process of machining parts on CNC machine tools. A CNC machine tool is a machine tool controlled by a computer. The computer used to control the machine tool, whether it is a dedicated computer or a general-purpose computer, is collectively referred to as a CNC system. Before large-scale CNC machining, you must clearly see the content of the process flow, clearly know the part, shape, and dimensions of the workpiece to be processed, and know the processing content of the next process.

What are the precautions for the daily operation of CNC machining?

Before processing raw materials and clamping, measure whether the blank size meets the requirements of the drawing, and carefully check whether its placement is consistent with the programmed instructions.

After the rough machining of the processing technology is completed, self-checking should be carried out in time, so as to adjust the data with errors in time.

The main content of self-inspection is the position and size of the processing part.

(1) Whether there is looseness in the machining process of mechanical parts;

(2) Whether the part processing technology is correct to touch the starting point;

(3) Whether the size of the large CNC machined part to the reference edge (reference point) meets the requirements of the drawing;

(4) The position and size of the cnc processing parts relative to each other. After checking the position dimension, measure the rough machined shape ruler (except arc).