Finishing

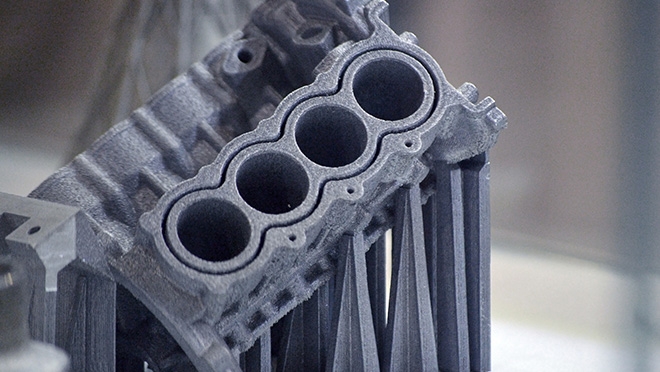

Stainless steel metal printing sample

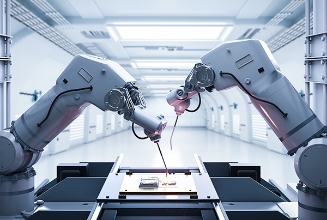

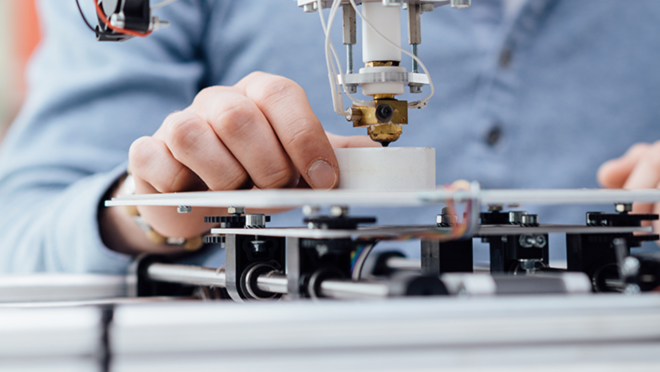

The engineer inputs the original 3D design drawing file into the SLA/SLS program. SLA/SLS will layer the parts. Establishing the supporting structure of the part is an important step. The rationality of the support structure design will directly affect the degree of deformation of the parts during the printing process and will affect the final quality of the product. In the product printing stage, the photosensitive resin or powdered material is cured or sintered in layers by ultraviolet or laser technology, and finally, the post-production processing process of the entire prototype sample is completed through the continuous stacking of layers, and the surface and support structure of the parts are cleaned. It is also necessary to cure the prototype sample to achieve a predetermined strength.

What is a 3D printing technology

- 3D printing is a revolutionary technology. Today’s industrial 3D printing is mainly divided into SLA and SLS.

- SLA mainly produces plastic prototype samples, SLS can produce plastic and hardware parts (steel, aluminum alloy, titanium alloy, etc.).

- 3D printing is different from CNC processing. CNC processing is to remove unwanted materials by milling or turning processes, while 3D printing is just the opposite, which is a processing method that directly superimposes materials.

- 3D printing from the original drawings to the provision of prototype samples, the entire production process is simple and efficient, so the production speed is fast.

- 3D printing can be produced as a whole without requiring the complex geometry of prototype samples.

Small Molded Parts within Days

Our complete CNC aluminum service will accompany your aluminum machining project from the prototype construction to the end aluminum parts manufacturing.

Common Materials

There are a wide variety of materials that can be machined using technology, Huayu provides machining quotes for more than 30 engineering-grade plastic and metal materials.

| Name | Description | Feature |

|---|---|---|

SLA

SLA

|

The photosensitive resin is the dedicated 3D printing material for SLArapid prototyping. | Lightweight Low cost prototypes |

SLS

SLS

|

Nylon is a durable material with great impact strength, medium flexibility,and high resistance to environmental factors. | Corrosion resistance Aesthetic appeal |

FDM

FDM

|

This material is a thermoplastic aliphatic polyester and it is the primarynatural raw material used in 3D printing. | Lightweight Low cost prototypes |

We can source any other materials upon request! If you don’t see the material you need please contact us

How Does Multi Jet Fusion Work?

Uses an inkjet array to selectively apply fusing and detailing agents across a bed of nylon powder, which are then fused by heating elements into a solid layer. After each layer, powder is distributed on top of the bed and the process repeats until the part is complete, powder is distributed on top of the bed and the process.

When the build finishes, the entire powder bed with the encapsulated parts is moved to a processing station where a majority of the loose powder is removed by an integrated vacuum. Parts are then bead blasted to remove any of the remaining residual powder before ultimately reaching the finishing department where they are dyed black to improve cosmetic appearance.

Industry Application

We’ve manufactured millions of parts for all sorts of applications, empowering diverse industries with top-notch products: industrial machinery, medical, AI industrial, Transportation, etc.

Frequently Asked Questions

What are your maximum dimensions for CNC machining?

What are the tolerances of machined parts?

What's your CNC machining capacity?

How much does your CNC machining service cost?

Manufacturing Resources

Put your parts into production today