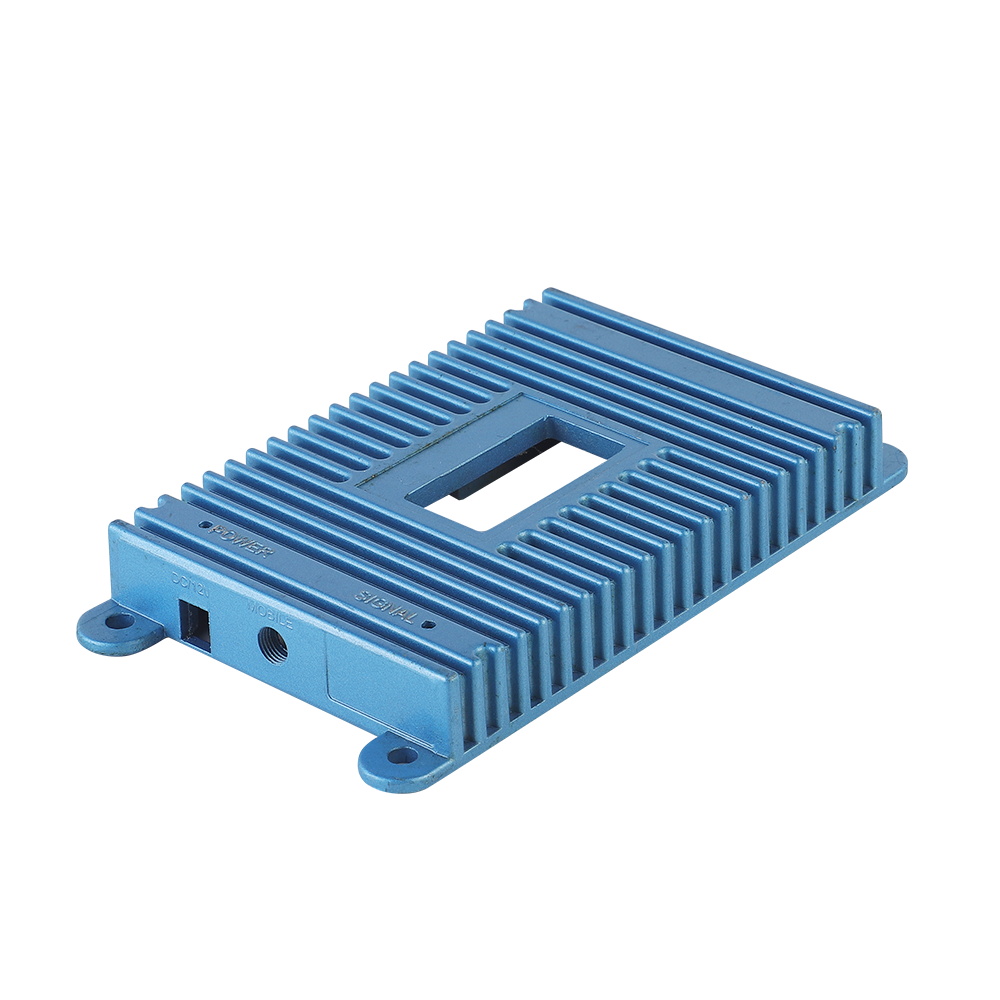

Communication aluminum alloy shell for die casting

Process: Processed using advanced CNC milling and precision stamping processes.

Surface Treatment: Anodized and may be spray painted or silk screened.

Minimum Tolerance +/-1 micron

Material: Made of high strength 6061-T6 aluminum alloy material, may be heat treated.

Other information:

Designed with engineering dustproof protection,

and internally designed with heat sinks and heat sinks.

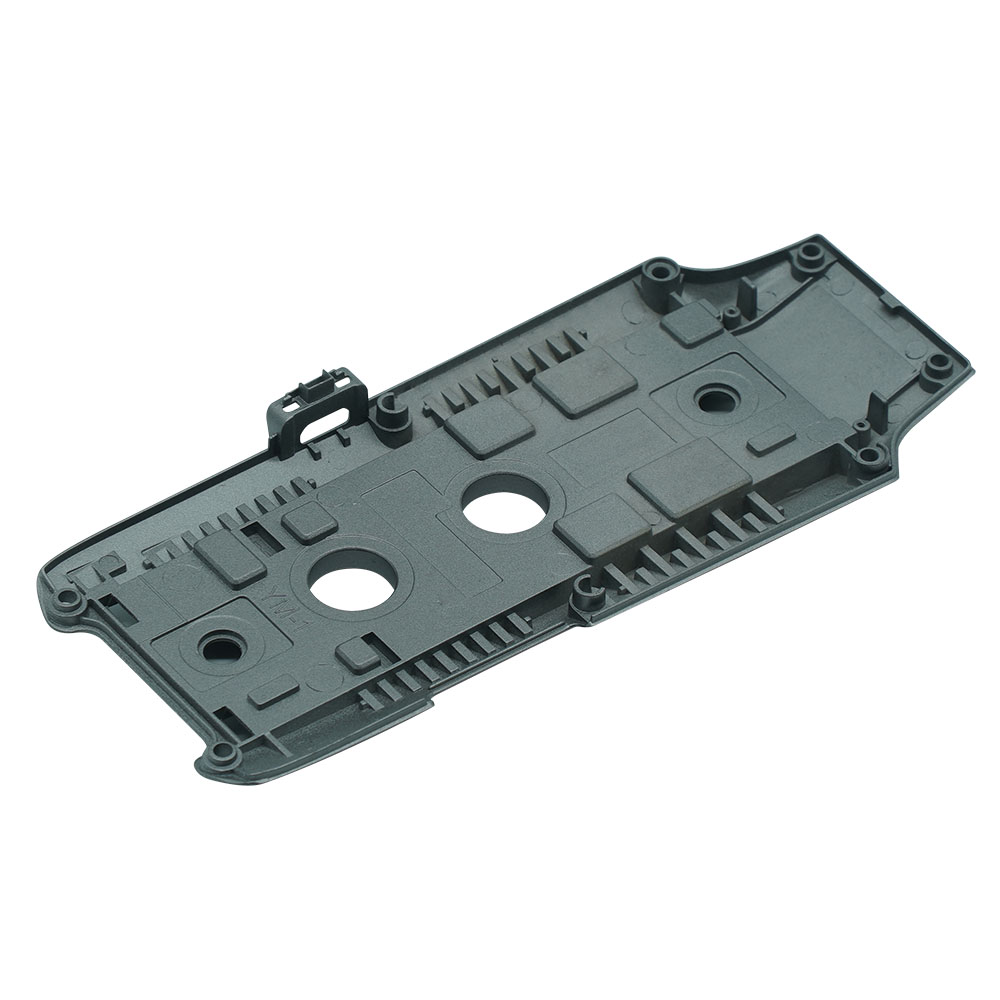

High Precision PC144R Injection Molded Parts

The injection molded parts we produce with pc144r have strong insulation, are suitable for LED lamp housing parts, are anti-aging, and will not fade after long-term use. They can be delivered within 30 days at the fastest, with a daily output of 5,000 pieces.

Process: injection moulding

Material: PC144R

Application: LED lamp housing parts

Characteristics: anti-aging, anti-corrosion, high temperature resistance

Delivery time: 30 days

Daily output:5000pcs

120A Terminal Box – Circuit breaker housing

OTHER configuration:

Material: IDI BMC 46-12

Processing difficulty: prevent the product appearance dull

Process: Injection moulding

Surface treatment: Polishing, deburring

End customer: Tokyo Electric Power

3D Printed Metal Parts

OTHER configuration:

Dimensional accuracy: 0.1 mm

Surface roughness: 10 microns

Mechanical properties: high strength and wear resistance

Weight: lighter than implants produced by traditional manufacturing methods, helping to reduce the burden on patients

Producibility: complex 3D structures, which are difficult to achieve using traditional manufacturing methods, can be easily achieved with 3D printing technology

AGV &AMR custom cover plate

OTHER configuration:

XY-GLOBAL focuses on the development and production of industrial-grade mobile robot structural parts, realizing the technology of robot assembly, synthesis and operation, etc. If you are interested in AGV-related structural parts, please contact our engineers

Aluminum Bead Blasted, Anodized End Caps

OTHER configuration:

High Precision Customized Die Cating Part

1) Material: Aluminum Alloy: ADC12, A380, A360 Zinc Alloy: ZINC#3 ZINC#5

2) Process: Die Casting Process, CNC Machining Process

3) Finish: Powder Coating, Anodized, Oil Painting, Chroming ect.

4) Tolerance: +/- 0.1mm

Aluminum CNC machined electronic product housing parts

OTHER configuration:

OEM/ODM Customized CNC Machinery Parts for Hardware Part

1) Material: Aluminum, Copper, Stainless Steel

2) Process: CNC Machining, CNC Lathe

3) Finish: Anodized, Electroplating, Sandblasting, Polishing

4) Tolerance: +/- 0.005mm

Aluminum CNC machining link accessories

OTHER configuration:

OEM/ODM Customized CNC Machinery Parts for Hardware Part

1) Material: Aluminum, Copper, Stainless Steel

2) Process: CNC Machining, CNC Lathe

3) Finish: Anodized, Electroplating, Sandblasting, Polishing

4) Tolerance: +/- 0.005mm

Aluminum Die Casting Small Helicopter Parts

OTHER configuration:

Aluminum die-casting cut fruit model

OTHER configuration:

Aluminum extruded heat sink

Process: Processed using advanced CNC milling and precision stamping processes.

Surface Treatment: Anodized and may be spray painted or silk screened.

Minimum Tolerance +/-1 micron

Material: Made of high strength 6061-T6 aluminum alloy material, may be heat treated.

Other information: Designed with engineering plastic inserts to provide waterproof and dustproof protection, and internally designed with heat sinks and heat sinks.

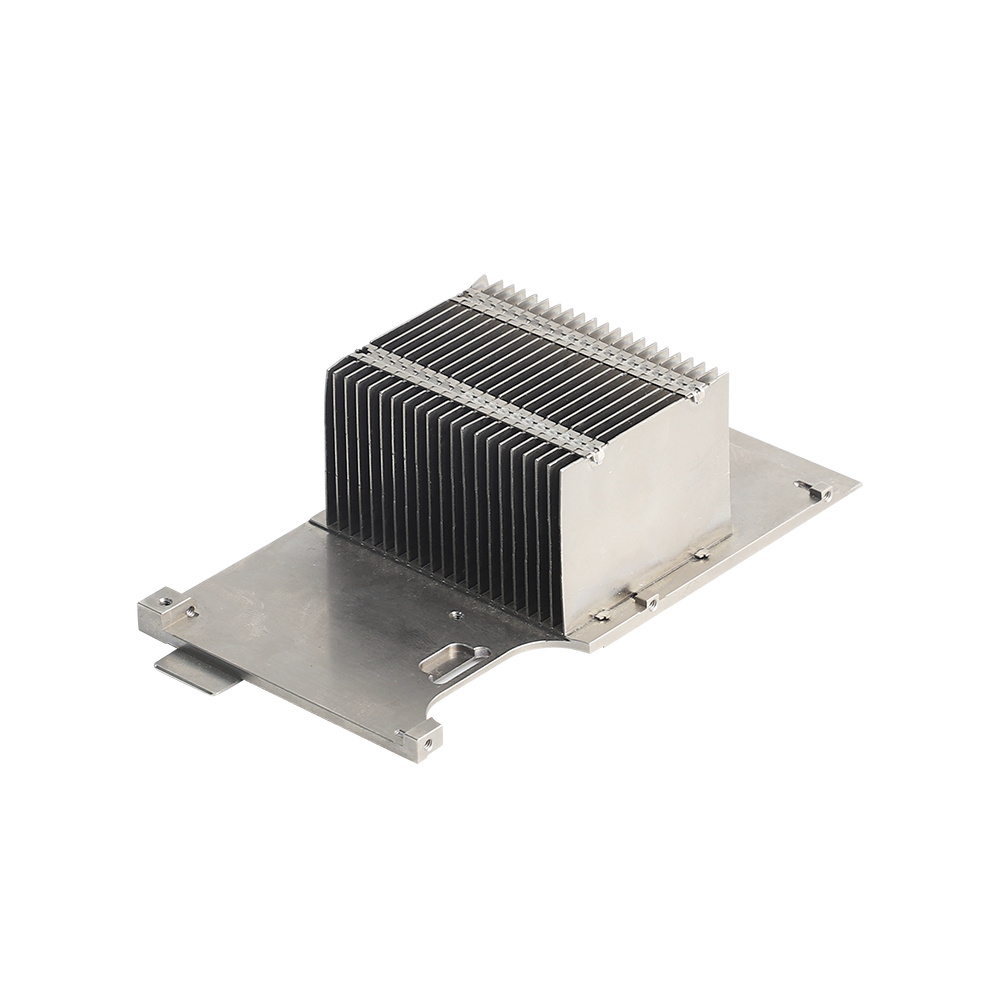

Aluminum Extruded Heat Sink Air Cooled Heat Sink Parts

OTHER configuration:

Process: Aluminum extrusion techniques, ensuring precise and efficient production of air-cooled heat sink components.

Surface treatment: Includes anodizing for improved corrosion resistance and thermal performance,

Minimum tolerance: +/-0.1 millimeters,

Material: Constructed from high-purity aluminum alloys, providing excellent thermal conductivity and heat dissipation properties for effective cooling.

Additional Information: Designed with optimized fin structures and airflow channels to maximize heat dissipation efficiency. Engineered for compatibility with a wide range of electronic products, from LED lighting to power electronics.

Aluminum extrusion forming electronic heat sink parts

OTHER configuration:

Process: Crafted with precision via aluminum extrusion techniques for consistent heat sink quality and performance.

Surface treatment: Utilizes anodizing or similar methods to boost corrosion resistance and thermal conductivity, enhancing heat dissipation.

Minimum tolerance: Maintains tight +/-0.1 millimeter tolerances for precise fit with electronic assemblies.

Material: Fabricated from high-grade aluminum alloys, chosen for superior thermal conductivity and mechanical strength, ensuring effective heat transfer and durability.

Additional Information: Engineered with intricate fin designs and airflow optimization for maximum cooling efficiency. Tailored to meet specific requirements of diverse electronic applications, ensuring reliable performance in demanding conditions.

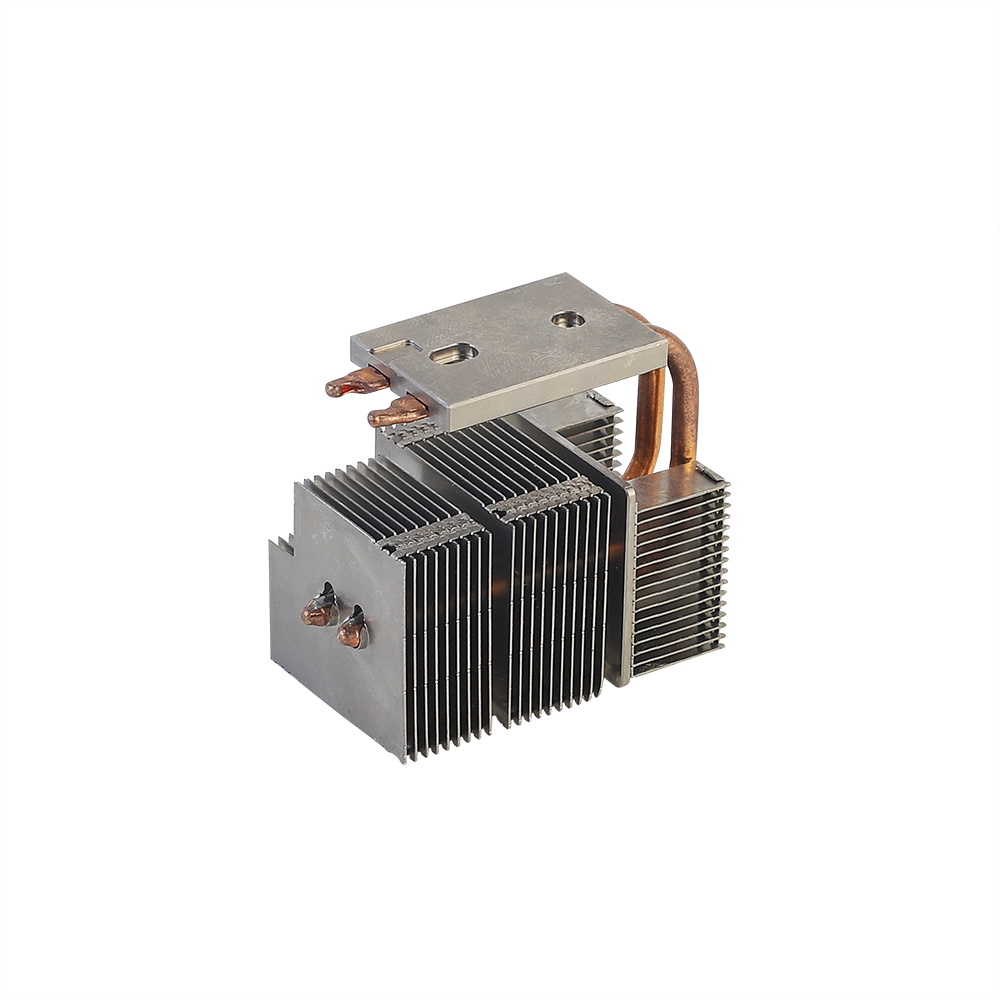

Aluminum extrusion forming heat sink for electronic products

OTHER configuration:

Process: Crafted through advanced CNC milling and precision stamping techniques, ensuring high-quality and precision.

Surface treatmen: includes anodizing, allowing for optional painting or silk-screen printing.

Minimum tolerance: +/-1 micron, ensuring precision and stability.

Material: Constructed from high-strength 6061-T6 aluminum alloy, capable of undergoing heat treatment for enhanced performance.

Additional Information: Incorporates engineered plastic components for waterproof and dustproof protection. Internal design features multiple heat dissipation fins, optimizing thermal management efficiency.

Aluminum Extrusion parts

OTHER configuration:

Process: Aluminum extrusion techniques, ensuring precise and efficient production of air-cooled heat sink components.

Surface treatment: Includes anodizing for improved corrosion resistance and thermal performance,

Minimum tolerance: +/-0.1 millimeters,

Material: Constructed from high-purity aluminum alloys, providing excellent thermal conductivity and heat dissipation properties for effective cooling.

Additional Information: Designed with optimized fin structures and airflow channels to maximize heat dissipation efficiency. Engineered for compatibility with a wide range of electronic products, from LED lighting to power electronics.

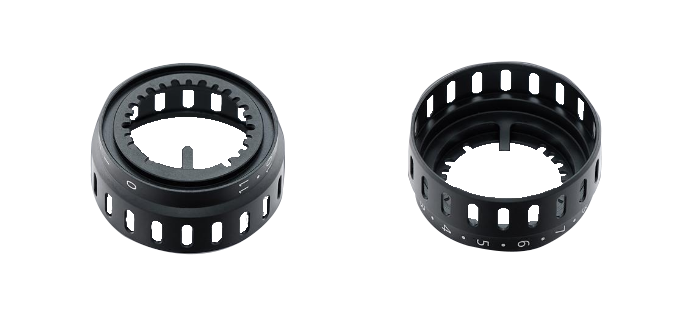

Aluminum Frame for optical lens-Optical Manufacturing

OTHER configuration:

Material: Aluminum, Copper, Stainless Steel

Dimensions:According to customer’s drawing.

Finish:Anodize,Sandblasting,Heat treatment,polishing,powder coasting,electroplating,spraying,

painting,silkscreen etc.

Tolerance:can reach to ±0.002mm

Quality control:100% inspected

Product

OEM/ODM Customized CNc Mechanical Hardware Fittings

1) Material: Aluminum, Copper, Stainless Steel Aluminum, Copper, Stainless Steel

2) Processing: CNC machining, CNC lathe.

3) Surface treatment: anodized, electroplated, sandblasted, polished.

4) Tolerance: +/-0.005mm +/-0.005mm

View More