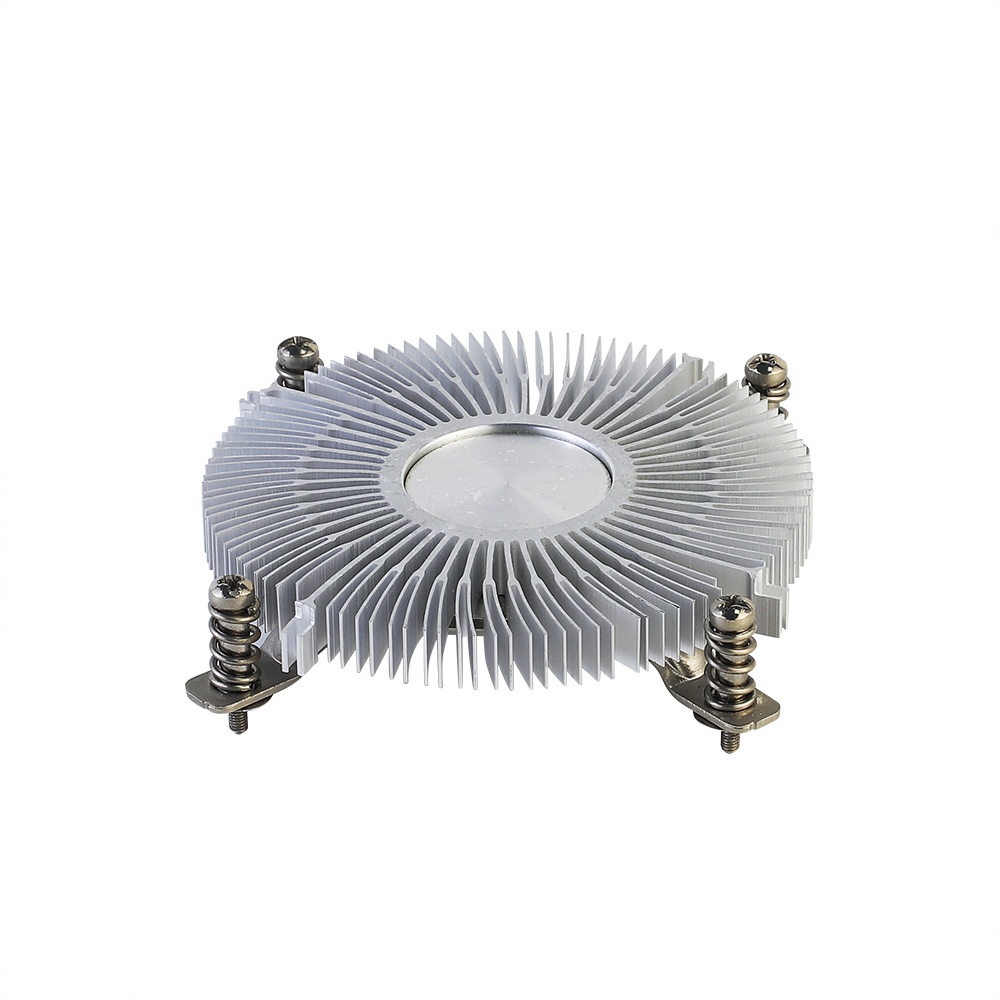

Aluminum extruded heat sink

Process: Processed using advanced CNC milling and precision stamping processes.

Surface Treatment: Anodized and may be spray painted or silk screened.

Minimum Tolerance +/-1 micron

Material: Made of high strength 6061-T6 aluminum alloy material, may be heat treated.

Other information: Designed with engineering plastic inserts to provide waterproof and dustproof protection, and internally designed with heat sinks and heat sinks.

Aluminum Extruded Heat Sink Air Cooled Heat Sink Parts

OTHER configuration:

Process: Aluminum extrusion techniques, ensuring precise and efficient production of air-cooled heat sink components.

Surface treatment: Includes anodizing for improved corrosion resistance and thermal performance,

Minimum tolerance: +/-0.1 millimeters,

Material: Constructed from high-purity aluminum alloys, providing excellent thermal conductivity and heat dissipation properties for effective cooling.

Additional Information: Designed with optimized fin structures and airflow channels to maximize heat dissipation efficiency. Engineered for compatibility with a wide range of electronic products, from LED lighting to power electronics.

Aluminum extrusion forming electronic heat sink parts

OTHER configuration:

Process: Crafted with precision via aluminum extrusion techniques for consistent heat sink quality and performance.

Surface treatment: Utilizes anodizing or similar methods to boost corrosion resistance and thermal conductivity, enhancing heat dissipation.

Minimum tolerance: Maintains tight +/-0.1 millimeter tolerances for precise fit with electronic assemblies.

Material: Fabricated from high-grade aluminum alloys, chosen for superior thermal conductivity and mechanical strength, ensuring effective heat transfer and durability.

Additional Information: Engineered with intricate fin designs and airflow optimization for maximum cooling efficiency. Tailored to meet specific requirements of diverse electronic applications, ensuring reliable performance in demanding conditions.

Aluminum extrusion forming heat sink for electronic products

OTHER configuration:

Process: Crafted through advanced CNC milling and precision stamping techniques, ensuring high-quality and precision.

Surface treatmen: includes anodizing, allowing for optional painting or silk-screen printing.

Minimum tolerance: +/-1 micron, ensuring precision and stability.

Material: Constructed from high-strength 6061-T6 aluminum alloy, capable of undergoing heat treatment for enhanced performance.

Additional Information: Incorporates engineered plastic components for waterproof and dustproof protection. Internal design features multiple heat dissipation fins, optimizing thermal management efficiency.

Aluminum Extrusion parts

OTHER configuration:

Process: Aluminum extrusion techniques, ensuring precise and efficient production of air-cooled heat sink components.

Surface treatment: Includes anodizing for improved corrosion resistance and thermal performance,

Minimum tolerance: +/-0.1 millimeters,

Material: Constructed from high-purity aluminum alloys, providing excellent thermal conductivity and heat dissipation properties for effective cooling.

Additional Information: Designed with optimized fin structures and airflow channels to maximize heat dissipation efficiency. Engineered for compatibility with a wide range of electronic products, from LED lighting to power electronics.