Shenzhen Optical Metal Parts Manufacturer – Providing the most advanced products and solutions.

Welcome to our website! We are a Shenzhen-based manufacturer of optical metal parts and accessories, dedicated to providing our customers with state-of-the-art products and solutions.

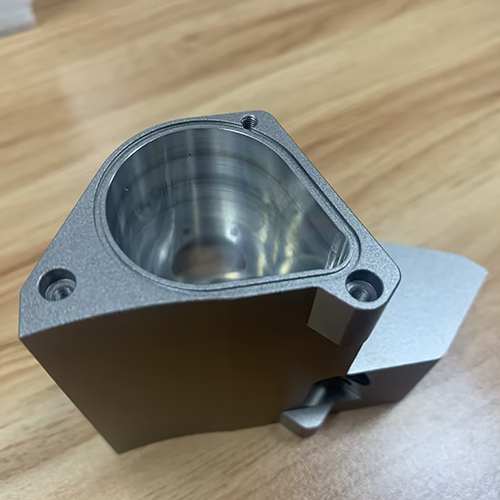

Recently, our customer from Algeria came from miles across the ocean to visit our company and attend a meeting where we showcased our customized optical metal parts products for each other and discussed how to iterate and upgrade for the next generation of products.

In manufacturing, there are a variety of ways to bring products to life, but not every method is suitable for all projects. Therefore, it is important to consider the available techniques to determine the most suitable method for a particular application. Today, we will explore CNC machining technology

CNC machining utilizes computer controls to automate processes traditionally done with manually operated equipment, and is capable of shaping raw materials into complex designs with unparalleled precision. Traditional machining, on the other hand, relies on skilled operators to manually guide tools through the manufacturing process and is rooted in traditional craftsmanship.

Efficient High Volume Production

Automated CNC machining methods minimize the need for manual intervention, resulting in faster, more consistent production throughout the manufacturing cycle. With pre-programmed instructions, CNC machines can replicate the same parts over and over again. This ensures product quality and minimizes the waste that can result from human error. In addition, modern CNC machines are incredibly fast and can produce large parts quickly.

Deciding on the machining technology for your project can be tricky, but after you’ve read this article, you should know which technology is right for your project. While traditional machining has a lower upfront cost, it’s not well suited for high-volume production. In this case, CNC machining technology is your best bet. However, you may need to incur higher initial costs.

Cost Savings

As production needs change, manufacturers can easily expand their CNC machining processes to provide flexibility for high-volume manufacturing. This flexibility in production capacity means that you can maximize your resources and budget without being limited by the number of parts you wish to manufacture.

In addition to the demonstration and discussion, our customer also recorded a blessing video for us. This video is an affirmation of our work and a recognition of our company’s strength. Our customers’ trust in our products and services is the best proof of our unremitting efforts.

Our team consists of experienced professionals with advanced technology and equipment. Whether it is product design, manufacturing or after-sales service, we strive to provide the best quality solutions with customer satisfaction as our ultimate goal.

Please browse our product pages to learn more about our product lines and technical capabilities. If you have any questions or need further information, please feel free to contact our customer service team. Thank you for choosing us and we look forward to working with you in the future!