Zinc Die Casting vs Aluminum Die Casting: What Are Their Differences

Die casting is a manufacturing technique suitable for the production of parts with complex designs that requires accuracy and large-scale production. The technique is compatible with metals, with popular ones being zinc, magnesium, and aluminum. Of these different materials, zinc die casting vs aluminum die casting is the most common comparison in metal fabrication.

Both materials have unique inherent properties and applications. However, the process further improves these properties. As a result, you need to understand die casting and its effects on the materials. This article compares aluminum die casting and zinc die casting so you can understand them and how to use the correct one.

Differences Between Zinc Die Casting vs Aluminum Die Casting

Aluminum die-castings and zinc die-castings possess unique performance characteristics that determine their applications. Here are common parameters to help you differentiate between these two materials and choose the right one:

Weight:

Zinc alloys have a higher density similar to steel, making them stronger and heavier than most die-casting materials. Pure zinc has a density of 5g/cm3, while aluminum has a density of 2.7g/cm3. Therefore, due to its higher density, it offers greater impact resistance and is a material of choice for manufacturing structural components.

Properties: The primary differences between zinc die-castings and aluminum parts lie in their mechanical properties. Here are the common characteristics and distinctions between these two die-casting materials:

-

Melting Point:

- Zinc has a lower melting point (420 ±0 ℃) despite its higher density. The melting point is a crucial parameter in die-casting as it determines the type of die-casting process you can use. Zinc’s lower melting point makes it more suitable for hot chamber processes. This also avoids mold degradation, increases production yield, reduces manufacturing costs, and dictates the choice of casting process. On the other hand, aluminum has a higher melting point (660 ℃), making it compatible with cold chamber processes but increasing costs and cycle times.

-

Thermal Conductivity:

- Zinc alloys have better thermal conductivity compared to die-cast aluminum, efficiently absorbing and dissipating heat. Hence, it is more suitable for producing parts that generate high heat or require effective heat dissipation, such as heat sinks or electronic components.

-

Corrosion Resistance:

- Zinc die-castings exhibit superior corrosion resistance compared to aluminum die-castings, making them more suitable for projects in harsh environmental conditions.

Mold Life: Due to the lower abrasiveness and lower melting point of zinc die-casting materials, the molds used for zinc die-casting do not need to be as robust. These characteristics, namely low abrasiveness and low melting point, lead to reduced mold damage and processing costs. Consequently, molds used for manufacturing zinc die-castings can endure over 1,000,000 injection cycles, whereas aluminum die-casting molds can only handle 100,000 cycles.

Surface Treatment: Both types of castings typically require secondary surface finishing options. Besides the process, the material type also determines whether parts require surface finishing. Zinc castings, unlike aluminum, do not have porosity after casting, resulting in smoother or patterned surfaces that require less compensatory surface finishing. Additionally, zinc is more compatible with surface treatment options such as electroplating, powder coating, painting, electrocoating, and anodization.

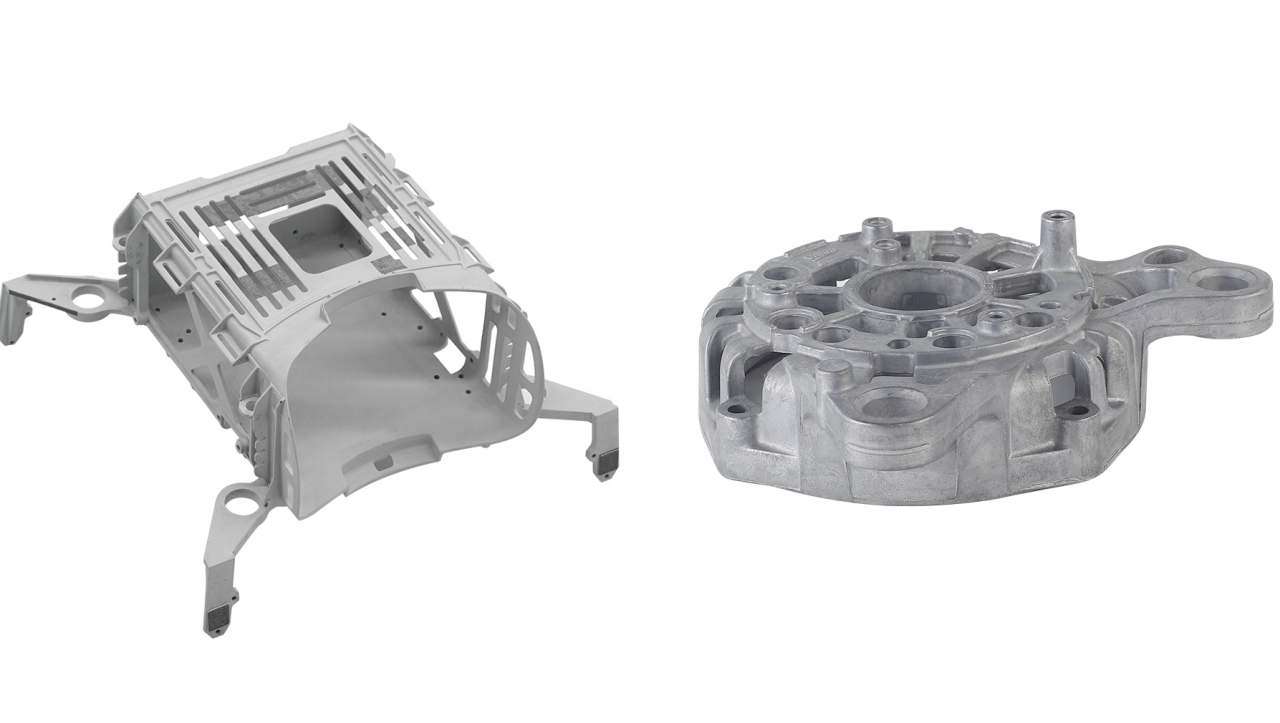

Applications: Both materials find applications in multiple industries. Zinc die-castings are stronger than aluminum die-castings, making them a more common choice for household appliances and automotive die-casting. Conversely, aluminum die-castings excel when lightweight yet strong parts are required, a crucial criterion in the aerospace industry.

These performance characteristics will aid in selecting the appropriate material for specific project requirements.

When and Why You Should Choose Zinc Die Casting

If you’re facing a decision between zinc die casting and aluminum die casting, consider the following factors that make zinc die casting a preferred choice:

If you’re facing a decision between zinc die casting and aluminum die casting, consider the following factors that make zinc die casting a preferred choice:

1. Thin-Walled Parts:

Zinc die casting is ideal for crafting parts with thin walls due to its exceptional strength compared to other materials. This ensures structural integrity and stability, reducing material usage and die-casting costs.

2. Harsh Environmental Conditions:

Zinc die casting excels in harsh environments, particularly those prone to corrosion. Its remarkable corrosion resistance forms a protective layer on parts when exposed to such conditions.

3. Lesser Residual Stress:

Die casting involves pressure to inject molten metal into molds. High-pressure die casting can sometimes lead to residual stress on parts. Zinc die casting, however, utilizes low-pressure die casting, reducing residual stress on components.

4. Die Cast Mold Durability:

Opt for zinc die casting when working with delicate die casting molds. Zinc die-casting molds can last approximately ten times longer than aluminum die-casting molds. Additionally, if you have budget constraints covering tooling costs, zinc die casting is a cost-effective choice.

5. Faster Production:

Zinc alloys have a low melting point, making them well-suited for the hot chamber die-casting process with high-pressure injection. This results in faster cycle rates compared to other materials. In zinc die casting, the zinc is melted directly within the machine, eliminating the need for manual aluminum melting before injection, as required in aluminum die casting.

These factors highlight the advantages of choosing zinc die casting for specific applications, offering durability, cost-efficiency, and faster production in challenging environments and scenarios.

When and Why Choose Aluminum Die Casting

When choosing aluminum die-casting over other die-casting options, several factors and circumstances should be considered:

Strength-to-Weight Ratio:

Aluminum die-casting is renowned for its lightweight nature and high tensile strength. Therefore, if you require components with an excellent strength-to-weight ratio, aluminum die-casting is the preferred choice. This is particularly crucial in industries like aerospace, where lightweight yet robust parts are essential.

High Operating Temperatures:

Aluminum die-casting is the preferred choice for high-temperature operating conditions, such as in the metallurgical industry. This preference arises from aluminum’s high melting point, ensuring the structural and physical stability of components when exposed to elevated temperatures.

Conductivity:

Aluminum die-casting boasts excellent electrical conductivity, making it the preferred material for numerous electronic die-cast components. For instance, in electromagnetic interference (EMI) shielding, protecting components from electromagnetic signals is paramount, and high conductivity aids in effectively shielding against these signals.

In summary, aluminum die-casting excels in applications requiring lightweight construction, high tensile strength, resistance to high temperatures, and superior electrical conductivity. Therefore, it is a wise choice in such circumstances.